Home » Our Products

Reach out to us for inquiries, orders, or collaborations. We’re here to serve you!

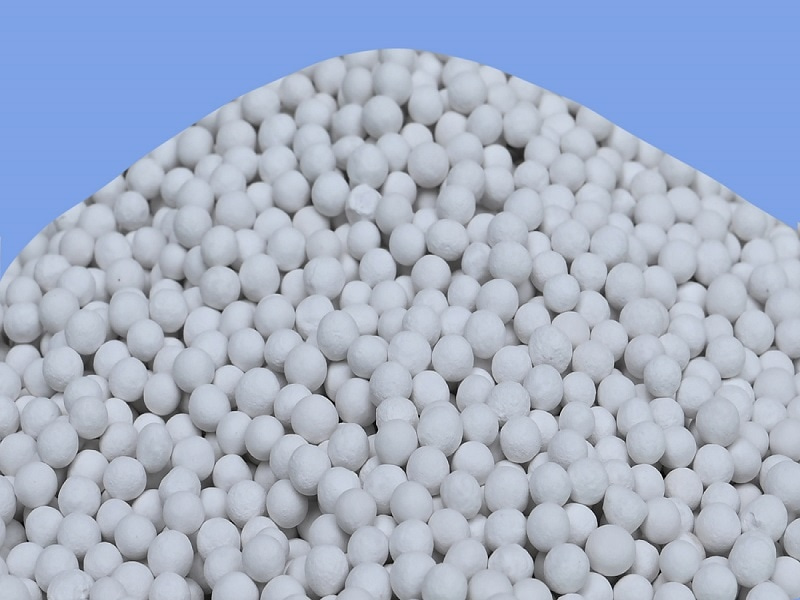

Activated alumina might not steal the spotlight, but behind the scenes, this remarkable material plays a critical role in countless industrial processes. This highly porous and reactive form of aluminum oxide acts as a workhorse in various applications, from purifying water to extending the life of machinery.

The Secret Lies in Activation

Regular aluminum oxide undergoes a special activation process, typically involving high heat treatments or chemical treatments. This process creates a highly porous structure with a vast internal surface area. It’s this extensive surface area that grants activated alumina its remarkable properties:

A Boon for Diverse Industries

The unique properties of activated alumina translate into a wide range of applications across various sectors:

Market Growth and a Sustainable Future

The global activated alumina market is expected to witness steady growth in the coming years, driven by several factors:

Activated Alumina: A Sustainable Ally

Activated alumina can be regenerated through heating or chemical treatment, allowing for multiple reuse cycles. This reusability reduces waste generation and contributes to a more sustainable industrial future.

Unlocking Potential with Activated Alumina

Activated alumina’s versatility, efficiency, and sustainability make it an indispensable material for various industries. By incorporating activated alumina into your processes, you can achieve improved product quality, enhance efficiency, and contribute to a more sustainable future. Contact us today to explore how activated alumina can benefit your specific needs.

Reach out to us for inquiries, orders, or collaborations. We’re here to serve you!

Bentonite isn’t your average clay. This naturally occurring aluminum silicate mineral boasts a unique structure that unlocks a remarkable range of applications across various industries. From enhancing soil health to cleaning up oil spills, bentonite’s versatility, further amplified by variations like sodium and calcium bentonite, makes it a valuable material in our world.

Born From Volcanic Ash:

Bentonite is formed through the weathering of volcanic ash, primarily composed of a clay mineral called montmorillonite. This special clay has a sheet-like structure with microscopic pores and a high cation exchange capacity (CEC). These properties are key to bentonite’s diverse functionalities, and the type of cation (positively charged ion) dominant within the clay structure significantly impacts its behavior. Here’s where sodium and calcium bentonite enter the scene:

Choosing the Right Bentonite Type:

Understanding the key differences between sodium and calcium bentonite is crucial for selecting the optimal type for your needs. Here’s a quick guide:

Bentonite’s Impact Across Industries:

Bentonite’s diverse properties, further amplified by sodium and calcium variations, make it a valuable asset in numerous sectors:

Bentonite: A Sustainable Choice

Bentonite is a naturally occurring and abundant clay, making it a sustainable material choice. Additionally, its ability to improve soil health, remediate environmental damage, and act as a carrier for controlled release of agricultural chemicals contributes to a more sustainable future.

Considering Bentonite for Your Needs?

Bentonite comes in various forms, including granules, powders, and even organoclays (modified with organic compounds). Choosing the right type, whether sodium, calcium, or a blend, depends on your specific application. By understanding the unique properties of bentonite and its variations, you can unlock its potential to enhance your processes and products.

Reach out to us for inquiries, orders, or collaborations. We’re here to serve you!

Colloidal nano silica, often shortened to CNS, might sound like something out of science fiction, but it’s a real and impactful material transforming various industries, particularly construction. This suspension of ultra-fine silica particles offers a powerful combination of properties that enhance performance and unlock new possibilities.

Unveiling the Power of Size: The Nano Advantage

CNS stands out due to its incredibly small silica particles, typically ranging from 2 to 150 nanometers (nm) in diameter. This nano size grants CNS unique properties:

Strength in Small Packages: Benefits for Construction

In the world of construction, CNS offers significant advantages:

Beyond Construction: Unveiling Diverse Applications

The potential of CNS extends far beyond construction:

Choosing the Right CNS for Your Needs

CNS comes in various forms, with different particle sizes and surface properties. Selecting the optimal type depends on your specific application. Understanding these variations is crucial for maximizing the benefits of CNS.

The Future of Construction and Beyond

Colloidal nano silica, with its unique properties and diverse applications, is poised to play a significant role in shaping the future of construction and various other industries. By harnessing the power of these tiny titans, we can build stronger, more durable structures, explore innovative applications in drug delivery and electronics, and contribute to a more sustainable future.

Embrace the Potential of CNS: Contact us today to learn more about how CNS can be incorporated into your projects.

Reach out to us for inquiries, orders, or collaborations. We’re here to serve you!

GGBS, or Ground Granulated Blast Furnace Slag, isn’t just an industrial byproduct; it’s a game-changer in the construction industry. This finely ground material, derived from iron production, offers a remarkable combination of strength-enhancing properties and environmental benefits, making it a sustainable choice for modern concrete.

Strength in Numbers: Unveiling the Benefits of GGBS

GGBS isn’t just about adding a fancy name to your concrete mix. Here’s how it elevates concrete performance:

Beyond Strength: The Environmental Edge of GGBS

GGBS isn’t just strong; it’s sustainable:

Applications: Where Does GGBS Shine?

GGBS finds favor in various concrete applications:

The Future of Sustainable Construction is Here

As the demand for greener building practices grows, GGBS is poised to play a vital role. By incorporating GGBS into your concrete projects, you’re not just building structures; you’re contributing to a more sustainable future for our planet.

Embrace the Potential of GGBS: Contact us today to learn more about how GGBS can elevate your next construction project.

Reach out to us for inquiries, orders, or collaborations. We’re here to serve you!

Metakaolin isn’t your ordinary clay. It’s a highly reactive pozzolanic material derived from kaolin clay that undergoes a high-temperature calcination process. This transformation unlocks remarkable properties that are revolutionizing construction, particularly in the realm of Ultra-High-Performance Concrete (UHPC).

Unveiling the Power of Metakaolin:

Metakaolin’s magic lies in its high reactivity with calcium hydroxide (lime), a byproduct of hydration in portland cement. This reaction forms additional cementitious compounds, leading to a range of benefits, especially significant in UHPC:

The Metakaolin Advantage in UHPC:

Metakaolin is a critical component in UHPC formulations, playing a key role in achieving its exceptional properties:

The Rise of Metakaolin Beyond UHPC:

While metakaolin shines in UHPC, its exceptional properties extend to other applications:

A Look at the Market Potential

The global metakaolin market, driven by UHPC and other applications, is anticipated to witness significant growth in the coming years due to:

Metakaolin: Building a Stronger, Sustainable Future

Metakaolin is derived from naturally occurring kaolin clay, making it a sustainable material choice. Additionally, its use in UHPC and other concretes can lead to reduced CO2 emissions.

Unlocking Potential with Metakaolin

Metakaolin offers a powerful combination of enhanced performance, sustainability, and versatility. By incorporating this innovative material into your UHPC projects and exploring its potential in other applications, you can create stronger, more durable structures, and contribute to a more sustainable future. Contact us today to learn more about how metakaolin can benefit your construction endeavors.

Reach out to us for inquiries, orders, or collaborations. We’re here to serve you!

Microsilica grey, also known as silica fume, is a revolutionary pozzolanic material that has transformed the world of concrete construction. Composed of ultra-fine particles, microsilica grey significantly enhances the performance of concrete, making it the go-to choice for demanding projects.

Unleashing Superior Strength and Durability:

Microsilica grey’s exceptional finesse fills microscopic voids within concrete, leading to a denser and remarkably stronger matrix. This translates to significantly improved compressive and flexural strength. Studies show concrete incorporating microsilica grey can achieve up to 20-30% higher compressive strength compared to standard concrete (source: American Concrete Institute). This allows for the construction of buildings and structures that can withstand greater loads and stresses, making them ideal for high-rise buildings, bridges, and other critical infrastructure projects.

Durability You Can Rely On: The increased density achieved with microsilica grey significantly reduces permeability. This fortifies concrete against water ingress, harmful chemicals, and harsh environments, extending the lifespan of structures and minimizing maintenance costs in the long run. Research suggests that concrete with microsilica grey can exhibit a 50% reduction in chloride ion permeability compared to standard concrete (source: National Ready Mixed Concrete Association).

Enhanced Corrosion Resistance: Microsilica grey plays a crucial role in fortifying concrete’s resistance to chloride-induced corrosion, a major concern in coastal areas and for structures exposed to de-icing salts during winter months. By reducing concrete permeability, microsilica grey helps prevent chloride ions from reaching and corroding the reinforcing steel within the concrete.

Microsilica Grey: Applications and Market Impact

The exceptional properties of microsilica grey have driven its adoption across various construction sectors:

The global market for microsilica is expected to reach USD 2.8 billion by 2027, driven by increasing urbanization and infrastructure development projects (source: Grand View Research). Microsilica grey plays a vital role in this growth, as its properties ensure the longevity and sustainability of modern construction.

Building a Stronger Future with Microsilica Grey

Microsilica grey is more than just a concrete additive; it’s a foundation for stronger, more durable, and long-lasting structures. By incorporating microsilica grey into your concrete mix, you’re not just building structures, you’re building a future that endures. Contact us today to learn more about how microsilica grey can elevate your next construction project.

+91 93447 89767

+91 94440 36345

sales@m2exports.com

M2 Exports, Chennai – 600034

Exports India

M2 Exports India was incorporated in 2018 in Chennai, India.

Optimizing work hours for productivity, well-being, and work-life balance.

© Copyright 2024 M2 Exports India. All Rights Reserved by Digju.com